To know more about making zipper, please leave your contact info below. Our sales engineer will contact you withn 24 hours.

Traditional shoelaces were made of leather, cotton, jute, hemp, or other materials used in the manufacture of rope. Modern shoelaces often incorporate various synthetic fibers, which are generally more slippery and thus more prone to coming undone than those made from traditional fibers. On the other hand, smooth synthetic shoelaces generally have a less rough appearance, suffer less wear from friction, and are less susceptible to rotting from moisture. Specialized fibers like flame resistant nomex are applied in safety boots for firefighters.

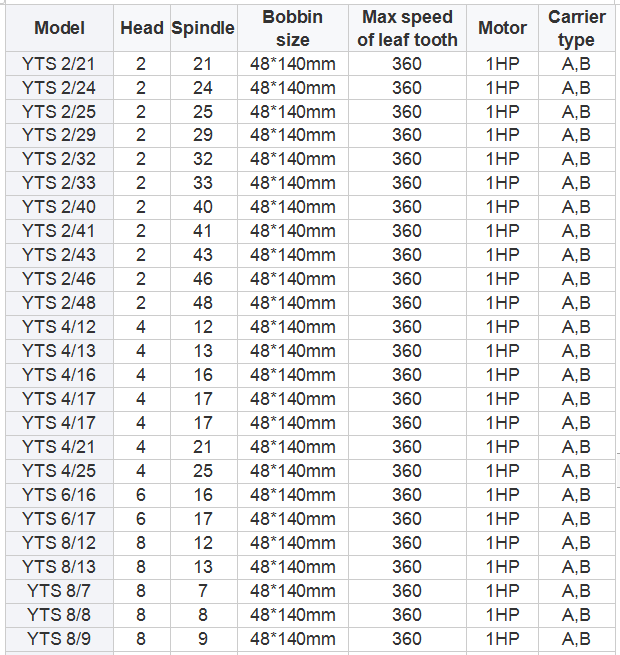

Yitai High Speed Braiding Machines are used to produce a variety of elastic or non-elastic ropes, draw cords, shoelaces etc.It comes with 2,4,6,8 heads with a number of spindles available such as 8,9,12, 13,16,17,21,24,32,40 etc. There are three bobbin sizes available 48*140mm,70*210mm.

Shoelacefull line production

Step 1

Yarn preparation

Double winding machine is used to wind yarns onto a bobbin.

Step 2

Shoelaces production

Braiding machine is used to produce shoelaces.

Step 3

Shoelace tipping

Tipping machine is used to tip shoelaces.

Just contact us for any information need.

Post time: Nov-05-2021