Factory making Textile Braiding Machine - YTB-C 8/45/384 jacquard needle loom – Yitai

Factory making Textile Braiding Machine - YTB-C 8/45/384 jacquard needle loom – Yitai Detail:

Application

The machine is suitable to produce various types elastic and elastic jacquard tapes, such as jacquard underwear tape, jacquard bag tape, jacquard shoes laces, jacquard rope.

Yitai YTB-C high speed computerized jacquard needle loom machine features

The jacquard head tested 30 days everyday with 24 hours in our factory at 1400RPM, without any spare parts broke.This machine has 2 to 14lines, width can produce from 2mm to 110mm by different models.The jacquard hooks up to 1100 for more complex jacquard patterns.The stable production speed is up to 1000 RPM/Min.Magnetic valve cap, from the overall pressure to one by one pressure, easier to detect problem and lower cost to maintain.Imported bearings such as NSK, NTN, FAG etc. to ensure quality.Reasonable back creel design for easy assembling and adaption.Back take-off device and beam creel are changeable according to buyers’ required.

Spare parts requirements

Please fill out the form by “ spare parts inquiry” if you have any spare parts requirement, and provide nameplate of the machine. Send drawing according to the spare parts manual, real spare parts need be provided if necessary.

Standard equipment:

Back creel, inverter, rubber feeder

Optional attachment:

Back take-off deviceFront take-off deviceDouble take off rollerSingle take off rollerRubber rollerDouble weft double latch needleDouble weft single latch needleExtra long chainWarp feeder – belt typeBeams

| YTB-C Series Specification | |||||||||

| Jacquard needles▷Machine width▽ | 192 | 256 | 320 | 384 | 480 | 560 | 640 | 768 | |

| Machine model | 430 | 2/110 | 2/110 | 2/110 | 2/110 | 2/110 | 2/110 | ||

| 560 | 4/65 | 4/65 | 4/65 | 4/65 | 2/160 | 2/160 | |||

| 580 | 8/27 | 6/42 | 6/424/65 | 4/65 | 4/65 | 4/65 | |||

| 610 | 4/806/558/30 | 4/806/558/30 | 4/806/55 | 4/806/55 | 4/80 | 4/80 | |||

| 730 | 8/4510/30 | 8/4510/30 | 8/45 | 8/45 | |||||

| 860 | 10/458/55 | 10/458/55 | 10/458/55 | 10/458/55 | 8/55 | 6/808/55 | 4/1106/80 | 4/1106/80 | |

| Motor | 2HP;Double rapid | ||||||||

| Speed | 800-1000 RPM | ||||||||

| Heald frame | 2-8 PCS | ||||||||

| Design chain circle | 8-40 | ||||||||

| Weft density | 3.5-36.7 WEFT/GM | ||||||||

| Normal attachment | 27-36 Yarn creel places,Software,Jacquard Normal attachment | ||||||||

| Optional attachment | Rubber feeder , Double hook single needle system,Beam,Frequency conversion timingCAD plate soft | ||||||||

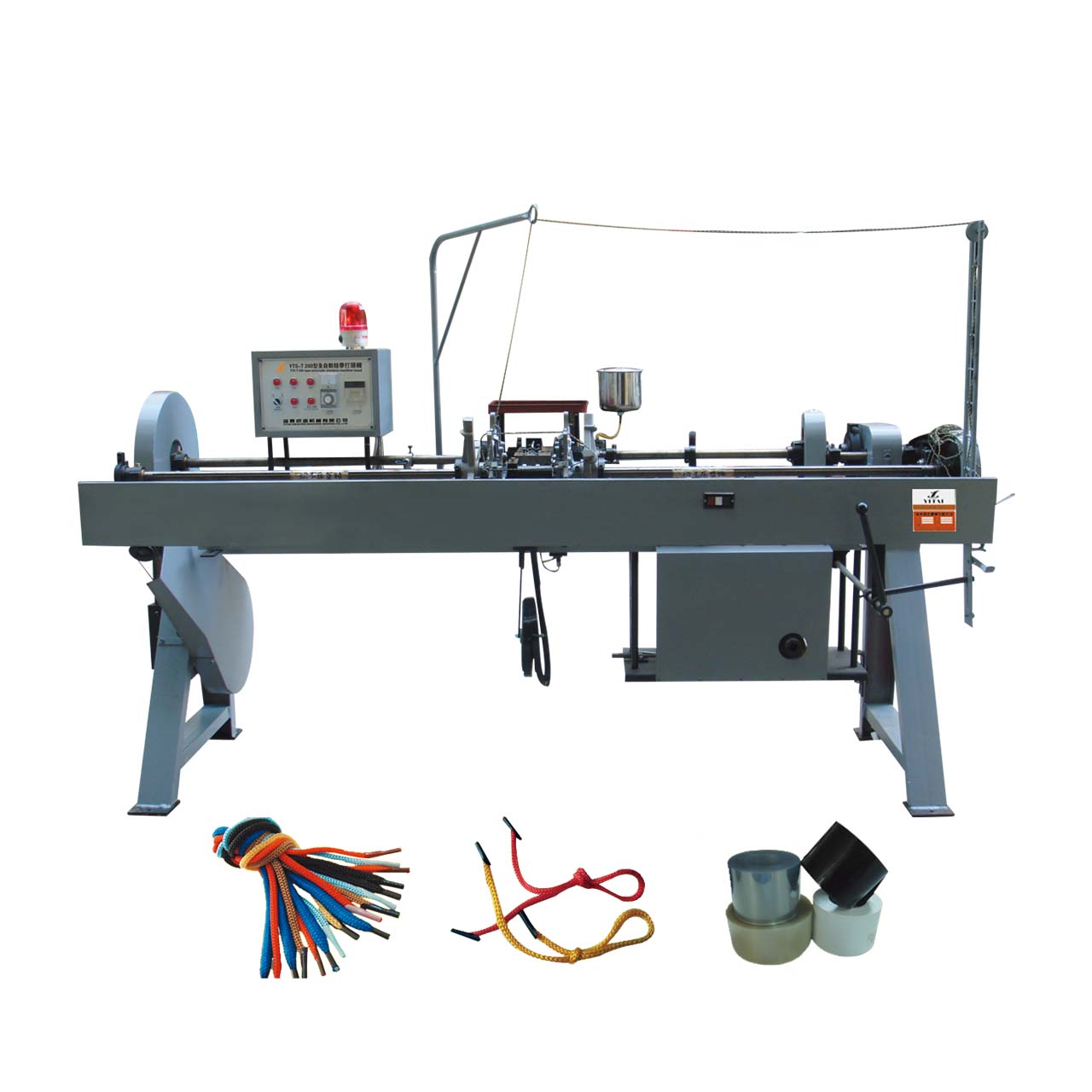

Product detail pictures:

Related Product Guide:

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Factory making Textile Braiding Machine - YTB-C 8/45/384 jacquard needle loom – Yitai , The product will supply to all over the world, such as: Accra, Vietnam, Egypt, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

Parts list (More other spare parts available. Please contact us to get more spare parts details.)

| the front reed |  |

test |

| weft needle |  |

|

| crochet needle |  |

|

| needle |  |

|

| heald |  |

|

| Drop wires |  |

|

| selvedge plate |  |

|

| Aluminum hand |  |

|

| shedding lever |  |

|

| heald frame-middle |  |

|

| heald frames assem |  |

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.